Le changement d'accessoires sur une pelle peut être un processus long et physiquement exigeant, obligeant souvent l'opérateur à quitter la cabine. Cela fait non seulement perdre de précieuses heures de travail, mais augmente également le risque d'incidents de sécurité sur le chantier. Le besoin de changements d’accessoires plus efficaces, plus sûrs et plus rapides est essentiel pour maximiser la productivité et minimiser les temps d’arrêt.

La méthode traditionnelle de suppression manuelle des pièces jointes peut ralentir la progression, en particulier lorsque plusieurs types de pièces jointes doivent être utilisés dans un même projet. Dans les opérations à grande échelle, ce processus peut entraîner des retards importants, une efficacité moindre et une augmentation des coûts de main-d'œuvre. De plus, les risques de sécurité associés aux changements manuels d'accessoires, tels que l'exposition à des machines en mouvement et aux dangers potentiels du site, ne peuvent être ignorés. Sans l'attache rapide appropriée, les projets de construction sont moins efficaces, plus dangereux et sujets à des retards évitables.

Les types d'attaches rapides pour excavatrices sont spécialement conçus pour résoudre ces problèmes, permettant aux opérateurs de basculer rapidement et en toute sécurité entre différents accessoires, tout en restant dans le confort et la sécurité de la cabine. Ces coupleurs sont disponibles en plusieurs types, chacun répondant à différentes exigences de projet et besoins opérationnels. Que vous ayez besoin d'une attache manuelle, hydraulique ou entièrement automatique, l'attache rapide appropriée peut contribuer à accroître l'efficacité, à réduire les temps d'arrêt, à améliorer la sécurité et, en fin de compte, à améliorer la productivité globale sur le chantier.

En investissant dans l'attache rapide appropriée, vous pouvez rationaliser vos opérations, gagner un temps précieux et vous assurer que votre pelle est équipée pour répondre aux besoins spécifiques de votre projet.

1. Types d’attaches rapides pour excavatrice – Attache rapide manuelle

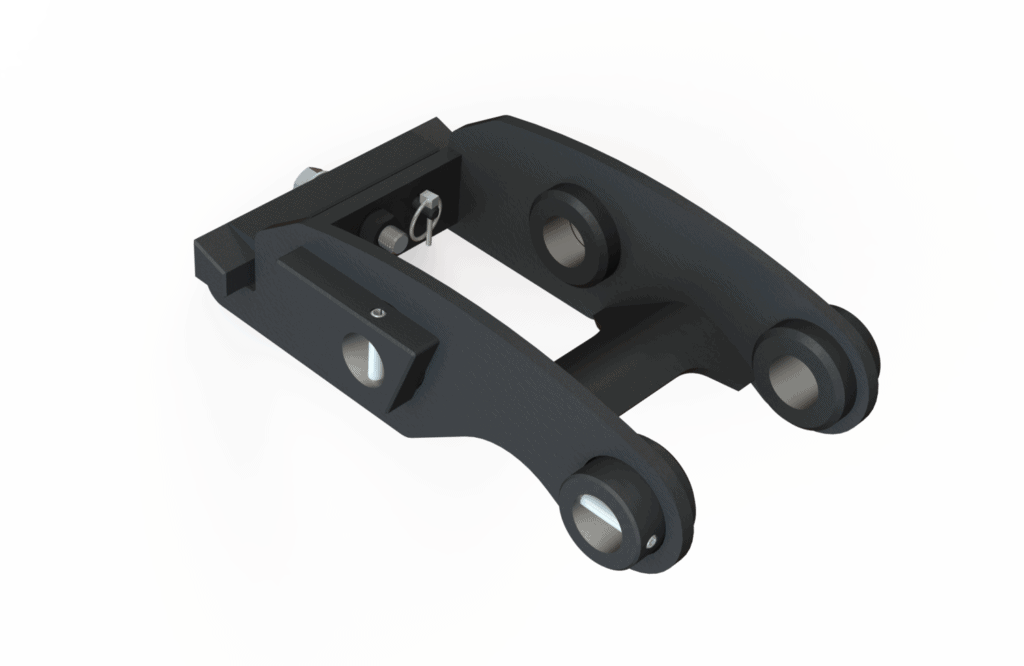

- Aperçu: L'attache rapide manuelle est le type le plus basique, conçu pour des changements d'accessoires simples nécessitant une intervention manuelle. L'opérateur verrouille ou déverrouille manuellement l'accessoire en actionnant une goupille ou un mécanisme de verrouillage. Ce coupleur est largement utilisé en raison de sa simplicité et de sa rentabilité, en particulier dans les opérations à petite échelle ou les tâches nécessitant des modifications minimes des accessoires.

- Avantages:

- Rentable: L'attache rapide manuelle est souvent moins chère que ses homologues hydrauliques du fait de l'absence de mécanismes complexes.

- Simplicité: Il est facile à utiliser et à entretenir, avec moins de pièces à craindre par rapport aux systèmes hydrauliques.

- Faible entretien: Il est facile à entretenir car aucun composant hydraulique ou électrique n’est impliqué, ce qui signifie moins de points de défaillance potentiels.

- Inconvénients:

- Prend du temps: Étant donné que l’opérateur doit engager et désengager manuellement les accessoires, cela est plus lent que les autres systèmes, ce qui réduit l’efficacité globale.

- Risques pour la sécurité: La nécessité de quitter la cabine de l’opérateur pour changer manuellement les accessoires expose l’opérateur à des risques potentiels pour sa sécurité, tels que des machines en mouvement et des chutes de débris.

- Polyvalence limitée: Le mécanisme manuel peut être plus encombrant lors du passage fréquent d'un accessoire de grande taille à un autre.

- Idéal pour :

- Petits travaux de construction, tâches d'excavation simples ou opérateurs qui travaillent avec un ou deux types spécifiques d'accessoires et n'ont pas besoin d'effectuer des changements fréquents.

2 Types d'attaches rapides pour excavatrice – Attache rapide hydraulique

- Aperçu: Les attaches rapides hydrauliques sont plus avancées que les attaches manuelles et permettent à l'opérateur de changer d'outil sans quitter la cabine. Alimentés par des systèmes hydrauliques, ils sont largement utilisés dans des opérations à grande échelle où l'efficacité et la sécurité sont primordiales. Ce système utilise la force hydraulique pour libérer ou verrouiller l'accessoire, ce qui en fait une option plus rapide et plus pratique que le type manuel.

- Avantages:

- Efficacité accrue: Les accessoires peuvent être changés rapidement et en toute sécurité sans que l'opérateur ait à quitter la cabine, ce qui minimise les temps d'arrêt et améliore la productivité globale.

- Versatilité: Les attaches rapides hydrauliques sont idéales pour les opérations qui nécessitent un changement fréquent de divers accessoires tels que des godets, des marteaux et des grappins.

- Sécurité améliorée: L'opérateur reste dans la cabine, réduisant ainsi l'exposition aux dangers sur site et garantissant un fonctionnement plus sûr.

- Inconvénients:

- Cher: Les coupleurs hydrauliques sont plus chers que les options manuelles en raison de la complexité supplémentaire et du système hydraulique.

- Entretien: Les composants hydrauliques peuvent nécessiter un entretien régulier, et il existe un risque de panne du système hydraulique, ce qui pourrait entraîner des réparations coûteuses.

- Poids: Les composants hydrauliques ajoutés alourdissent ces coupleurs, ce qui pourrait affecter la capacité de poids globale de la pelle.

- Idéal pour :

- Projets de construction, de démolition ou miniers à grande échelle où des changements rapides d'accessoires sont essentiels pour une productivité maximale.

3 et 3 Types d'attaches rapides pour excavatrice – Attache rapide semi-automatique

- Aperçu: L'attache rapide semi-automatique combine des éléments des systèmes manuels et hydrauliques. Bien qu'il soit toujours à commande hydraulique, l'opérateur doit effectuer certaines tâches manuelles, telles que le verrouillage ou le déverrouillage de l'accessoire en place. Ce système hybride offre certains des avantages des coupleurs hydrauliques, tout en restant plus abordable que les systèmes entièrement automatiques.

- Avantages:

- Rentable: Offre un juste milieu en termes de prix, offrant certaines fonctionnalités hydrauliques sans les dépenses totales d'un système entièrement automatique.

- Changement de pièce jointe plus rapide: Bien qu'il ne soit pas entièrement automatique, il permet néanmoins des changements d'accessoires plus rapides que les systèmes manuels.

- Contrôle de l'opérateur: Certains opérateurs préfèrent le système semi-automatique car il fournit davantage de retour tactile pendant le processus de fixation, garantissant ainsi que les accessoires sont solidement verrouillés en place.

- Inconvénients:

- Implication manuelle: La nécessité de certaines actions manuelles limite encore l'efficacité globale du système, surtout par rapport aux coupleurs entièrement automatiques.

- Entretien: Bien que plus simple qu'un système entièrement hydraulique, le coupleur semi-automatique nécessite néanmoins un entretien des composants hydrauliques et mécaniques.

- Idéal pour :

- Les entrepreneurs qui ont besoin d’un équilibre entre contrôle manuel et efficacité hydraulique, mais qui n’ont pas besoin de systèmes entièrement automatisés. Idéal pour les projets de taille moyenne où les changements de fixations sont fréquents, mais pas constants.

4 Types d'attaches rapides pour excavatrice – Attache rapide universelle

- Aperçu: Une attache rapide universelle est conçue pour fonctionner avec différentes marques et types d'accessoires, offrant une flexibilité maximale aux opérateurs qui utilisent fréquemment différents types d'accessoires. Le coupleur universel s’adapte à plusieurs tailles et conceptions, ce qui le rend idéal pour les entrepreneurs qui travaillent avec une variété d’équipements de fabricants.

- Avantages:

- Versatilité: Le principal avantage est sa capacité à s'adapter à différentes marques et tailles d'accessoires. Il est parfait pour les entrepreneurs qui travaillent avec des équipements de plusieurs fabricants.

- Commodité: Avec un coupleur universel, vous pouvez facilement basculer entre les accessoires sans avoir à vous soucier des problèmes de compatibilité.

- Gain de temps: Les coupleurs universels aident à réduire le temps passé à changer d'outil, permettant ainsi d'effectuer plus de travail en moins de temps.

- Inconvénients:

- Problèmes de compatibilité: Bien que les coupleurs universels soient conçus pour fonctionner avec une grande variété d'accessoires, certains outils hautement spécialisés ou personnalisés peuvent ne pas s'adapter correctement.

- Coût plus élevé: En raison de leur nature polyvalente, les attaches rapides universelles ont tendance à être plus chères que les systèmes monomarques ou manuels.

- Idéal pour :

- Entrepreneurs travaillant avec une gamme d’équipements et d’accessoires provenant de plusieurs fabricants, en particulier dans le cadre de projets variés et à grande échelle.

5 Types d'attaches rapides pour excavatrice – Attache rapide entièrement automatique

- Aperçu: L’attache rapide entièrement automatique est l’option la plus avancée et la plus efficace disponible. Il permet à l'opérateur de changer d'accessoires sans quitter la cabine, en automatisant entièrement le processus de verrouillage et de déverrouillage. Ces coupleurs sont généralement utilisés dans des environnements à haute productivité où la minimisation des temps d'arrêt et l'optimisation de l'efficacité sont essentielles.

- Avantages:

- Vitesse: Les coupleurs entièrement automatiques constituent l'option la plus rapide, rendant les changements d'accessoires presque instantanés, augmentant ainsi considérablement la productivité sur le chantier.

- Sécurité: Puisqu’il n’est pas nécessaire de sortir de la cabine, l’opérateur court beaucoup moins de risques de blessures et la sécurité globale du chantier s’améliore.

- Commodité: L'opérateur a un contrôle total sur le changement d'accessoire depuis l'intérieur de la cabine, ce qui peut grandement rationaliser les flux de travail.

- Inconvénients:

- Cher: Les attaches rapides entièrement automatiques sont généralement les plus chères, à la fois en termes de coût d'achat initial et de maintenance continue.

- Complexité: Des composants plus complexes signifient plus de pièces à entretenir et un plus grand risque de pannes.

- Idéal pour :

- Projets à forte demande tels que la construction à grande échelle, l'exploitation minière ou la démolition où la vitesse et la sécurité sont primordiales et où des changements fréquents d'accessoires sont nécessaires.

6. Types d'attaches rapides pour excavatrice – Attache rapide à broche

- Aperçu: Les attaches rapides à goupille reposent sur un simple mécanisme de goupille et de verrouillage pour sécuriser les fixations. L'opérateur installe manuellement une goupille à travers l'accessoire et le coupleur pour maintenir les deux connectés. Ce système simple et traditionnel offre des fonctionnalités de base et convient aux environnements low-tech.

- Avantages:

- Simplicité: Le coupleur à broches est simple et facile à utiliser, sans composants complexes impliqués.

- Faible coût: C’est l’une des options les plus abordables, ce qui la rend idéale pour les entrepreneurs soucieux de leur budget.

- Fiabilité: Avec moins de pièces mobiles, ce type de coupleur est très durable et nécessite peu d'entretien.

- Inconvénients:

- Effort manuel: L'opérateur doit quitter la cabine pour fixer et retirer manuellement les goupilles, ce qui peut réduire l'efficacité.

- Changements d'attachement plus lents: Les systèmes à broches mettent plus de temps à basculer entre les accessoires que les systèmes hydrauliques ou automatiques.

- Idéal pour :

- Opérations à petite échelle, équipements plus légers et projets dans lesquels les changements d’accessoires sont peu fréquents et ne nécessitent pas de commutation à grande vitesse.

7 Types d'attaches rapides pour excavatrice – Attache rapide robuste

- Aperçu: Les attaches rapides robustes sont conçues pour les environnements difficiles et exigeants où les accessoires doivent supporter des charges lourdes et des conditions extrêmes. Ces coupleurs sont souvent utilisés dans des industries telles que l'exploitation minière, la démolition et la construction à grande échelle, où l'équipement est soumis à une utilisation rigoureuse.

- Avantages:

- Durabilité: Conçus pour résister aux conditions les plus difficiles, les attaches rapides robustes peuvent supporter plus d'usure que les attaches standards.

- Capacité: Ces coupleurs sont capables de manipuler des accessoires plus lourds et plus gros nécessaires aux travaux plus importants.

- Fiabilité: Les coupleurs robustes sont conçus pour une utilisation à long terme avec un temps d'arrêt minimal, ce qui les rend idéaux pour les environnements très sollicités.

- Inconvénients:

- Poids: Ces coupleurs sont généralement plus lourds, ce qui peut affecter l'équilibre et la maniabilité de la pelle.

- Coût: En raison de leur construction robuste et de leurs fonctionnalités supplémentaires, les coupleurs robustes sont plus chers que les autres types.

- Idéal pour :

- Opérations de haute intensité telles que des projets de démolition, d’exploitation minière ou d’excavation à grande échelle où l’équipement doit gérer des charges de travail importantes.

Conclusion

Le choix du bon type d'attache rapide pour votre pelle dépend en grande partie de vos besoins opérationnels spécifiques et de votre budget. Les coupleurs hydrauliques sont idéaux pour les travaux à grande échelle et urgents où l'efficacité et la sécurité sont primordiales, tandis que les coupleurs manuels ou à broches offrent simplicité et prix abordable pour les opérations à plus petite échelle. Pour les opérateurs qui ont besoin de polyvalence ou doivent travailler avec plusieurs marques d’accessoires, les systèmes universels ou hybrides peuvent offrir le meilleur équilibre entre performances et flexibilité. En fin de compte, comprendre les exigences de votre projet et la fréquence à laquelle vous devez changer les accessoires vous aidera à faire le meilleur choix.