Why is is important to know how do excavators work? I remember when I first started working in construction; we had a massive new job come in that involved a sizeable hole. My foreman decided that we needed an excavator to help with the huge hole, and I thought to myself if you could get a big enough shovel or backhoe, you could dig the hole with that instead of paying a machine to do it. So he had one delivered to the job site, and that’s when I realized I had no idea how one of those massive beasts worked other than the lowboy driver driving up to the site, unloading it off of the trailer and driving home.

It’s easy to take an excavator for granted, as long as it runs smoothly. However, if you don’t understand how the parts of an excavator work together, if you can’t mentally trace the path of fluid through the hydraulic system, you’ll run into trouble when something goes wrong. It may be a performance issue. It could be a mechanical issue. Or you could do something that damages the machine. Worse, you can become a hazard to yourself or others when working around a machine if you don’t understand how the machine works. Or, you’ll be late to the job site, end up leaving early because the excavator broke down, or you’ll be on your way to the repair shop.

In this article, we will break down how do excavators work, from the engine that powers them to the complex hydraulic systems that enable them to perform a range of tasks. Whether you are an operator, a beginner, or just interested in heavy machinery, this guide will give you a comprehensive understanding of how excavators work.

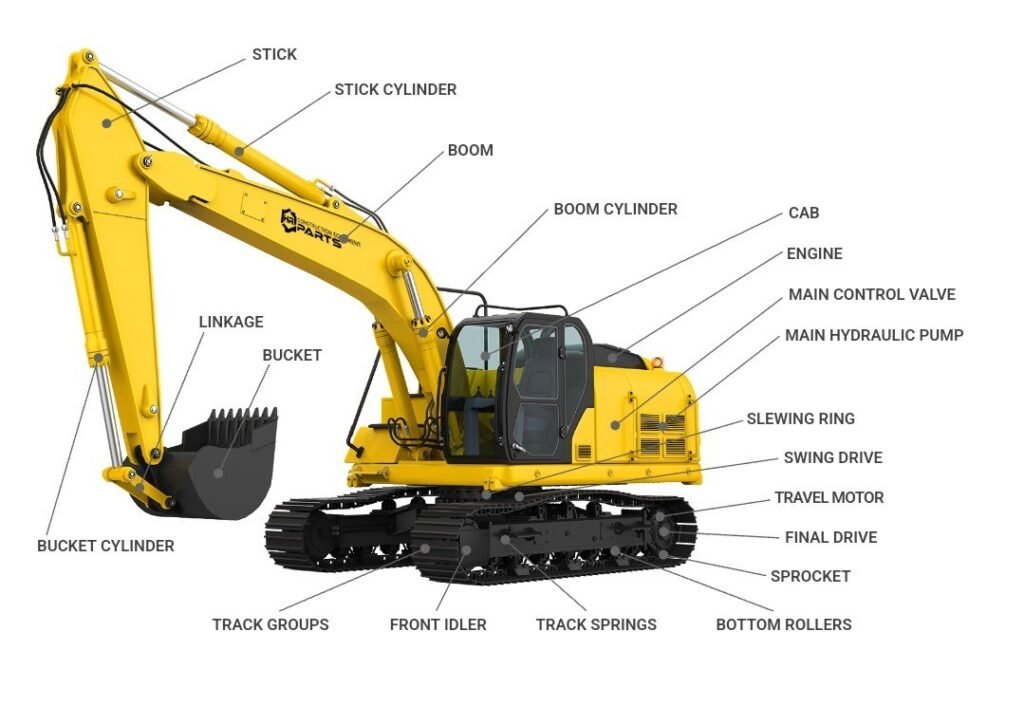

1. Basic Components of an Excavator

Before we get into how these beasts work, let’s talk about the basic components that make up a part of an excavator.

Key Components Include:

- Taxi: The cab is where the operator sits to control the excavator. The cab is also thought to be an enclosure mounted on the rotating superstructure. The cab can mount separately on the frame into which you enter on an industrial excavator. Inside sit the controls, joysticks, pedals, and visibility to safely operate the equipment.

- Boom: The boom is the big, long arm of the excavator that does the heavy lifting and extends to reach out to materials.

- Dipper Arm: The dipper is attached to the boom and provides improved control for moving the bucket or whatever your business is.

- Seau: On the end of the dipper arm is the business end, called a bucket. The bucket is what you use to dig, scoop, and transport the materials.

- Tracks or Wheels: Excavators are typically mounted on tracks (crawler excavators) or wheels (wheeled excavators) for mobility. Tracks are most often used for rough terrain.

- Système hydraulique: That is what powers almost everything on an excavator, including the boom, dipper arm, bucket, the entire hydraulic system, and the tracks.

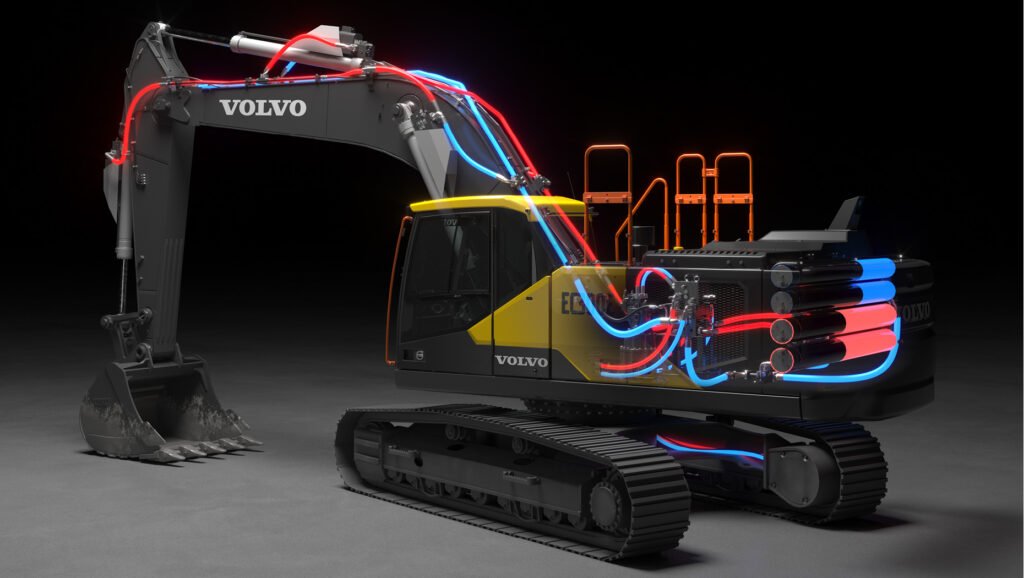

2. The Hydraulic System: The Heart of the Excavator

One of the most significant aspects of how an excavator works is the hydraulic system. The hydraulic system takes the low-pressure energy generated by the engine and converts it into high-pressure energy, ultimately allowing you to lift and dig with a machine.

How the Hydraulic System Works:

- Hydraulic Pumps:The engine runs hydraulic pumps that make hydraulic energy (usually oil) under pressure that circulates throughout the machine.

- Hydraulic Cylinders: The pumps provide hydraulic fluid to hydraulic cylinders that are on the boom, dipper arm, and bucket of the excavator. These cylinders use the hydraulic fluid to extend and retract. Let’s think about that for a moment. They use hydraulic fluid to move the boom and the bucket.

- Control Valves: Using the levers and joysticks in the cab, the operator controls the hydraulic system, able to divert hydraulic fluid to different parts of the machine.

- Hydraulic Fluid: The fluid sits in a tank or reservoir, and it flows through pipes all around the excavator to every part of the hydraulic system. You have to maintain the hydraulic fluid at the right level in the tank and periodically check it to ensure it isn’t contaminated to keep your system running well.

In short, the hydraulic system allows the excavator to exert tons of force with very little physical effort from the operator. Because of the hydraulic system, the excavator can lift heavy loads, dig holes in the ground, and do just about anything else you would want a unique machine to do.

3. Engine and Powertrain

The second part of an excavator is the engine. The engine generates the power needed to operate all of the systems on the machine. The power from the engine goes to the engine-driven hydraulic pumps, which provide the force required to make your machine move and operate all its parts.

How the Engine Works:

- Diesel Engine: Most people use diesel engines to power their excavators because they’re more robust and fuel-efficient for the amount of work you need to do. Diesel engines give you the horsepower you need to move your machine and run the hydraulic system.

- Transmission: The next part of the system is called the transmission. The transmission takes the power generated by the engine and converts it into movement for the tracks or wheels. Some machines have hydrostatic transmissions which are nice because they don’t jump and jerk you around like a gear-driven transmission. However, these are more expensive machines and more expensive to work on should something go wrong.

- Circuit de refroidissement: Below the cab and engine sits the radiator and cooling system. Excavators have cooling systems for the engine and hydraulic system to keep them from overheating while working. The coolant flows through the engine and other parts of the machine to keep everything working at the optimal temperature.

4. The Operator’s Role: Using Controls Effectively

Operators get to sit in the cab where they run the machine. But to run an excavator correctly, they have to know what they’re doing. They need to be able to run the levers and joysticks, which tell the hydraulic valves what to do. People who run these machines should have a pretty good idea of how they work because the better you can run one, the more money you can make with it.

Controls Involved:

- Joysticks: In most situations, there are two joysticks in the excavator cab. The left joystick controls the boom and dipper arm. The right joystick controls the bucket and swing. You can move these controls forward, backward, left, and right to control everything the machine does.

- Foot Pedals: In most cases, you have two foot pedals in the bottom of the cab. The left pedal controls forward and reverse movement. The right pedal – when it’s not specifically equipped for auxiliary hydraulic functions – is for your swing or turn in the machines with a back blade and swing motor on the back of the house.

- Throttle: By twisting a handle with one hand, they control how fast the engine is running. On an excavator, the faster the engine runs, the more power sent to the hydraulic system for hard digging and lifting.

- Swing Pedal: Many excavators also have a foot swing pedal. The faster you push on that pedal, the quicker the machine spins to the left or right for fewer movements with the joystick.

5. How Do Excavators Work: Moves with Tracks and Wheels

Either rubber belts or tires move excavators, which means you run them on tracks (track-mounted excavators) or wheels (wheeled excavators). The tracks or tires help move the machine around the job site.

Track-Mounted Excavators:

- Better Stability: The advantage track-mounted has over wheel excavators is that they give better stability, especially when working on rough or uneven ground. The track distributes the weight of the machine over a greater area, so they can work on softer or muddier ground without sinking in.

- Off-Road Capability: Because of that, they excel in rough terrain and off-road conditions, which is why you find them in construction, mining, and forestry applications.

Excavateurs à roues:

- Speed and Mobility: On the flip side, wheeled excavators are more mobile and quicker on hard, smooth surfaces like on urban roads or on a paved construction site.

- Maneuverability: Wheeled excavators are easier to manipulate in tight areas, but they are not as efficient on soft or uneven surfaces.

6. The Excavator’s Attachments: Enhancing Versatility

There is a wide array of attachments available for use with the excavator to perform different jobs. These attachments allow the machine to do specialized jobs beyond digging.

Common Excavator Attachments:

- Seaux: It is used for digging and scooping materials. You can get different types of buckets depending on the kind of work you do.

- Disjoncteurs hydrauliques: They are for breaking up hard materials like concrete or rock.

- Grappins: It is used for lifting and moving big objects.

- Tarières: Drilling tools used when you need to make holes in the ground.

- Rippers: Used for ripping through hard ground or rock.

Each attachment hooks to the hydraulic system on the excavator, so you can switch back and forth between tools whenever you need to do particular jobs.

7. Excavator’s Operation Cycle

There are several steps or cycles in the operation of an excavator that are repeated over and over as the machine digs, lifts, or loads material.

Phases of Operation:

- Digging Phase: The boom, dipper arm, and bucket work together to dig into the ground and then pick up whatever you want to put in the bucket. You can control the depth, angle, and pitch of the bucket so that you can dig accurately.

- Lifting Phase: You lift the material out of the hole and transport it to wherever you want it to go with the bucket. You lift the bucket with the boom and dipper arm to any height and distance you want.

- Swing Phase: The top part of the machine can rotate so you can place the material wherever you want it. You use the swing phase to place the material anywhere you need, be it right where you’re seated, over to one side to load a truck, or in a ditch to help fill it in.

- Dumping Phase:Then you dump the material out of the bucket, tilt the bucket back down flat, and then boom up and retract the dipper arm back preparing for the next cycle.

8. Excavator Safety Features

The manufacturer builds several safety features into the excavator for the safe operation of the machine.

Key Safety Features:

- Rollover Protective Structures (ROPS): In extremely rare cases, a machine might roll over. So, to protect you in the event of that happening, the manufacturer installs a ROPS system as standard equipment.

- Falling Object Protective Structures (FOPS): Falling Objects Protective Systems (FOPS) keep debris from falling on top of you.

- Emergency Stop Button: You also have a button to immediately stop the machine should something disastrous happen.

- Warning Alarms: Excavators are equipped with an audible alarm to notify the operator of possible dangers or unsafe conditions.

Conclusion

Excavators are powerful, versatile machines that depend on multiple systems working together. From the hydraulic system to the controls and even the attachments, every part is essential to how the machine operates. Understanding the parts and how they work together can help you operate the machine more efficiently, maintain the machine properly, and operate it safely on a job site.

By learning how excavators work, it will enhance your skillset, help you optimize your machine’s performance, and stop you from making many of the common mistakes others make. Whether you are running a small machine or a huge crawler, these principles apply across the board. After reading this, you should be able to operate any excavator without issue.